Training

Training center of "BPK"

"BPK" provides training of personnel for legal entities to work on machines with CNC. This program includes both training of machine operators and software engineers. The Training Center has been operating since 2007 and since 2017 is located on the territory of the new research and production complex BPK-NORTH.

For our customers we offer two training options: on the basis of our Training Center or on your production premises.

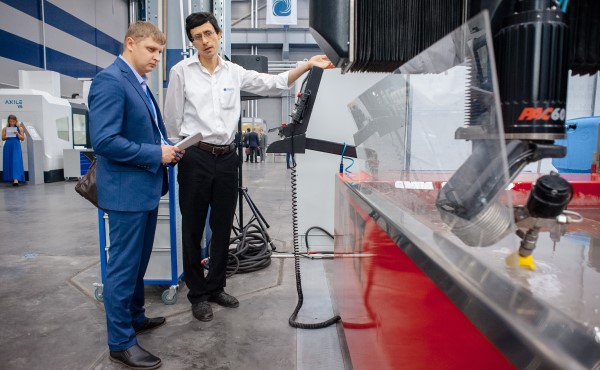

In addition to studying the basic theoretical material, it is compulsory to pass practical lessons for working out the acquired knowledge on the operating equipment of the Demonstration Hall. This allows in practice to get real skills in more than 50 metalworking machines.

In the Training Center, “BPK’s” specialists conduct training on a specially developed program. Applying an individual approach to training, we take into account not only the goals and objectives of the Customer, but also the basic knowledge and skills of students. Classes are conducted on the basis of certified training classes on CNC systems Siemens, Fanuc, Heidenhain.

Education on your production area

For your convenience, we also offer training for CNC machine operators at your production facilities. During the commissioning works, highly qualified specialists of our company will train operators on a specially developed program. After training, the operator will be able to work confidently on the machine, and also properly service it.

The training program includes:

- familiarization with the machine;

- introductory course of CNC;

- the operator panel;

- work with the axes and exit to zero;

- work with the spindle (S function);

- work with the tool store;

- work with proof-readers;

- coordinate system;

- auxiliary functions of machine control (M functions);

- creation and editing of programs;

- entering programs into the NC;

- work with subroutines;

- the basis of parametric programming;

- graphical display of program operation;

- input/output of programs;

- the device of the machine and its main components;

- maintenance of the machine.

Training in the work with the postprocessor NX (Unigraphics)

"BPK" together with the teachers of Saint-Petersburg Polytechnic University Peter the Great implements the program of advanced training of specialists for modern machine-building enterprises using CNC process equipment.

In the process of training, students of the program get knowledge about the device of modern software equipment and the principles of its functioning, the skills of its programming and management, as well as knowledge about the structure of technological preparation of production and skills in the field of development of technological documentation.