- Lathes

- CNC lathes with horisontal bed

- CNC Lathes with subspindle

- Conventional lathes

- With rotary head

- Two-pallet vertical machining center

- 5 Axis Machining Centers

- 5 Axis Machining Centers HSM series

- 5 Axis Machining Centers TVMC series

- 5 Axis Machining Centers MT series

- 5 Axis Machining Centers G series

- 5 Axis Machining Centers GF series

- Double Column Machining Centers PC series

- Double Column Machining Centers FS series

- Double Column Machining Centers LS series

- Double Column Machining Centers с подвижной траверсой SBM series

- Double Column Machining Centers с подвижным порталом SD series

- Double Column Machining Centers с подвижным порталом и подвижной траверсой SDW series

- Horizontal Boring Machines

- CNC Horizontal Boring Machines с подвижной колонной и выдвижным ползуном

- Conventional Horizontal Boring Machines FK series

- Horizontal Machining Centers HS series

- Horizontal Machining Centers MH series

- Surface grinding machines PSGS series

- Surface grinding machines PSGC series

- Surface grinding machines PSGO series

- Двухстоечные плоскошлифовальные станки серии PSGP

- Cylindrical grinding machines PSRC series

- Cylindrical grinding machines PSRP series

- Conventional cylindrical grinding machines GU series

- CNC cylindrical grinding machines OCD series

- Internal grinding machines IG series

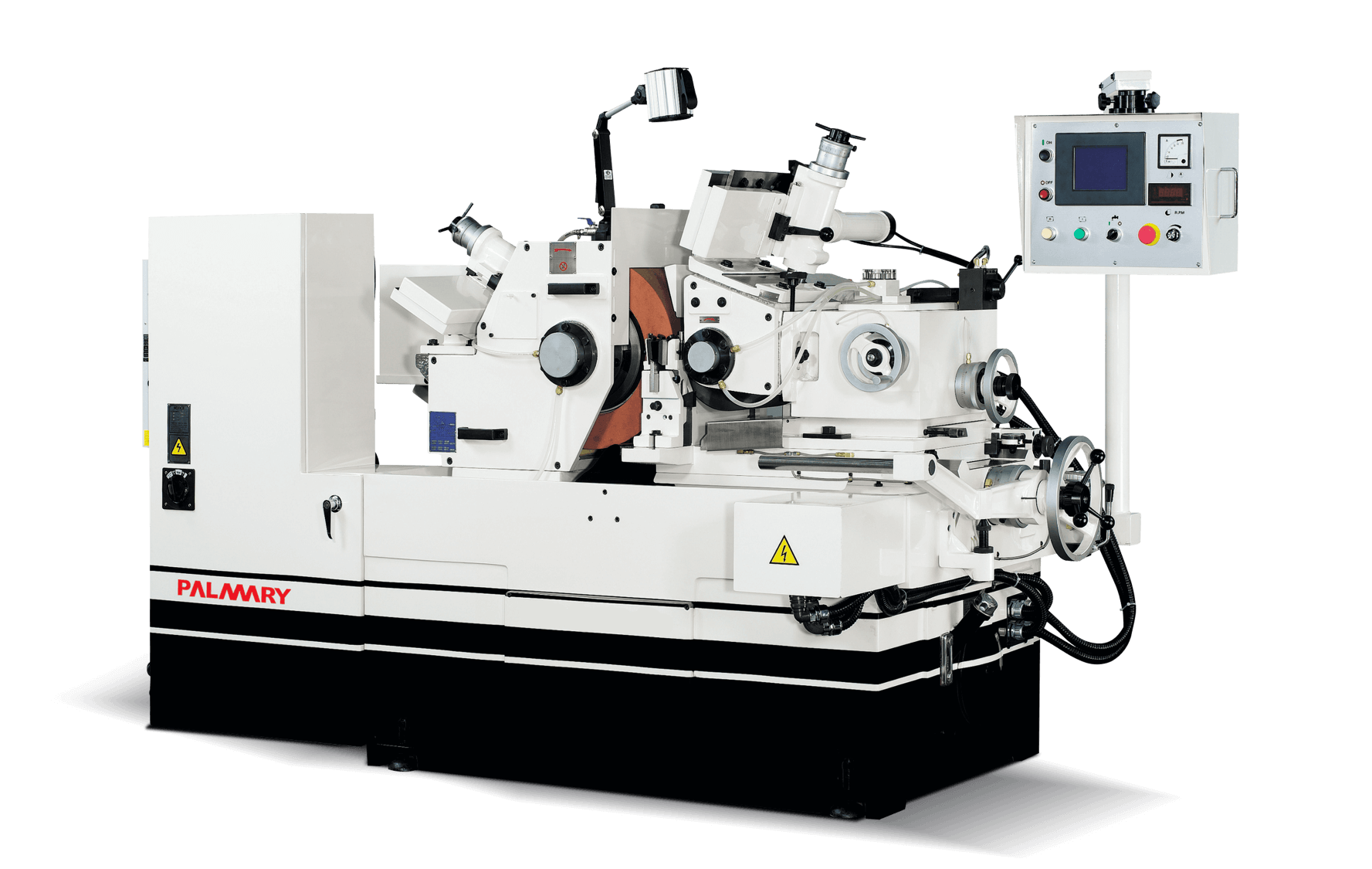

PC-20-NC

Availability

in stock

0

| Standard grinding range (dia.) | Ø1~80 mm |

| Capacity increases with special arrangement | Ø40~150 mm |

| Grinding wheel size (O.D. x width x I.D.) | Ø510 x 205x Ø304,8 mm |

Description of construction

- The GW spindle and the RW spindle are precision machined and made from alley steel, processed with normalization, aging, and heat treatment, then proceed to sub-zero treatment, finally finished after precision machining and grinding.

- The feed screw is manufactured from alloy steel. It's also normailzed, high frequency harden and precision ground in order to have high feeding accuracy and excellent wear resistance.

- When starting the GW and RW spindle, this pressure switch allows starting only when oil enters into bearings thereby providing safety protection for the spindle bearings.

- The automatic lubricator provides lubrication to the GW spindle. Also all slideways are lubricated by a centerlized lubrication system, ensuring proper lubrication and feeding accuracy.

Main features

| Grinding wheel | |

| Standard grinding range (dia.) | Ø1~80 mm |

| Capacity increases with special arrangement | Ø40~150 mm |

| Grinding wheel size (O.D. x width x I.D.) | Ø510 x 205 x Ø304.8 mm |

| Grinding wheel speed | 1200 r.p.m. |

| Grinding wheel motor | 20 HP x 4P |

| Regulating wheel | |

| Regulating wheel size (O.D. x width x I.D.) | Ø305 x 205 x Ø127 mm |

| Regulating wheel speed 10 ~ 300 r.p.m. (variable) | 10~300 r.p.m. (variable) |

| Regulating wheel motor | 5 kW servo motor |

| Regulating wheel tilt angle | +5° ~ -3° |

| Regulating wheel swivel angle | ±5° |

| Handwheel graduation | |

| Upper slide feed graduation | 3.5 mm/rev. ; 0.05 mm/graduation |

| Upper slide micro-feed graduation | 0.1 mm/rev. ; 0.001 mm/graduation |

| Lower slide feed graduation | 9 mm/rev. ; 0.05 mm/graduation |

| Trimming device graduation | 2mm/rev. ; 0.01 mm/graduation |

| Motor | |

| Hydraulic pump motor | 1 HP x 4P |

| Coolant motor | 1/4 HP x 2P |

| Machine dimension | |

| L x W x H | 2350 x 1900 x 1530 mm |

| New weight | 3600 kg |

Completion of the machine

Standard equipment:

- Grinding wheel and flange

- Infeed work rest and carbide blade

- Thrufeed work rest and carbide blade

- Electric system

- Hydraulic system

- Coolant system

- Diamond tools

- Work lamp

- Tools and tool box