As part of the agreements signed in June 2018 with the Government of the Ryazan Region on the development of machine-tool construction, "BPK" invests significant funds in the technical re-equipment and modernization of the machine-tool plant "Sasta" and the Sasovo Foundry.

Sasovsky Foundry

- A new melting plant with a capacity of 3.5 tons is expected to be delivered. This will make castings of cast iron weighing up to 6200 kg. In addition, it will be possible to duplicate the Inductotherm smelter in service.

- Modernization of the existing melting plant Inductotherm is carried out: replacement of the cooling system, transformer, TPCH, inductors and refractory plates.

- A new cooling tower is put into operation, which will significantly increase the productivity, especially in the summer, and exclude downtime.

- Work is underway to build a new annealing chamber 8 meters long.

- Purchased and installed new equipment in the factory laboratory, which will, as a result of even more accurate analysis and testing, almost completely eliminate the possibility of industrial rejection.

- Reconstruction of the roof of the foundry and general cosmetic repairs are underway.

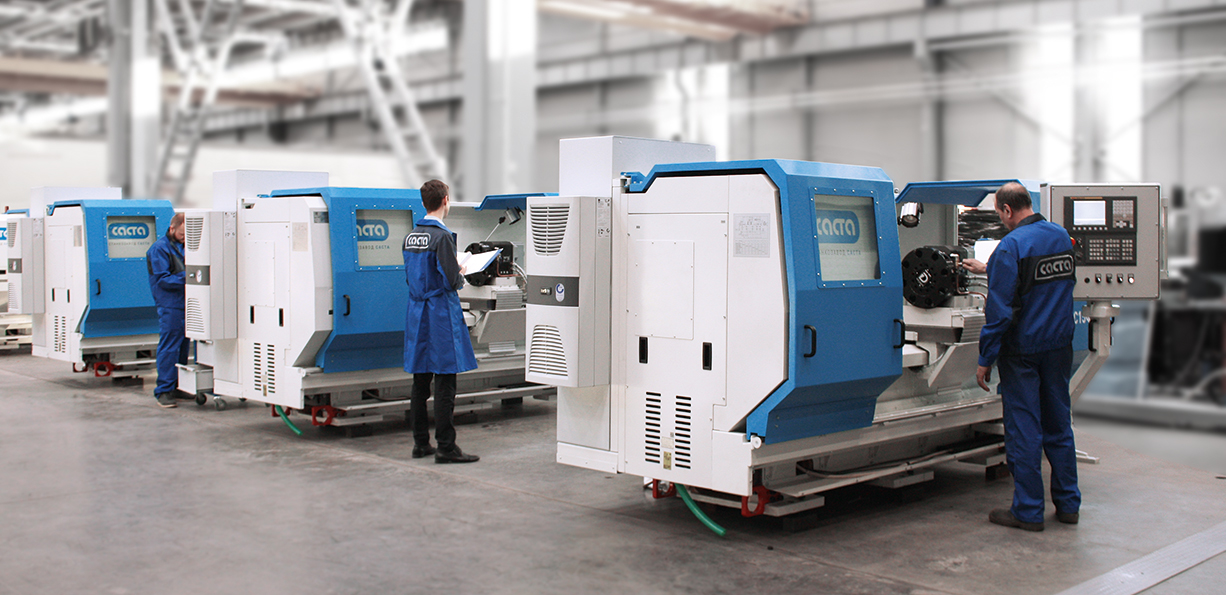

Machine-tool plant "Sasta"

- At the welding-procuring section, the water-jet cutting machine T6000, produced by F.O.R.T., Russia, was put into operation. Waterjet cutting has a number of undeniable advantages over thermal types of metal cutting. This is the lack of heating of the cut workpieces, that is, there is no thermal impact on the material, which eliminates thermal stresses and deformations of the material being processed. Ultimately, this prevents hardening, deformation, and contamination by elements such as harmful fumes and gases inherent in other types of cutting during processing. And one more important plus - there is no dust. To date, this machine has allowed us to increase the thickness of the sheet processed to 150 mm.

- A new laser cutting machine with CNC BySmart Fiber 3015x2000 mm manufactured by Bystronik, Switzerland, was launched and is functioning. This equipment allowed to increase the thickness of the processed sheet material to 12 mm, and to expand its range, including the processing of stainless steel and sheets of non-ferrous metal.

- Promulgated delivery machine Promau S.R.l. (Italy) DAVI MCA 2520. The working shaft length is 2550 mm, the maximum thickness of the folded sheet is 8 mm.

- There is a recruitment for workers and administrative specialties.

- A system of industrial practice for universities and colleges of Sasovo and the Ryazan region, Moscow State Technological University "Stankin" and St. Petersburg Polytechnic University Peter the Great was launched.